Full ioLogik Case Study Collection

'Developing Gigabit Fiber Networks for Toll Enforcement', 'Enabling Flexible Monitoring Systems for CNC Machines', 'Enabling an Energy-efficient HVAC System for a Hypermarket'

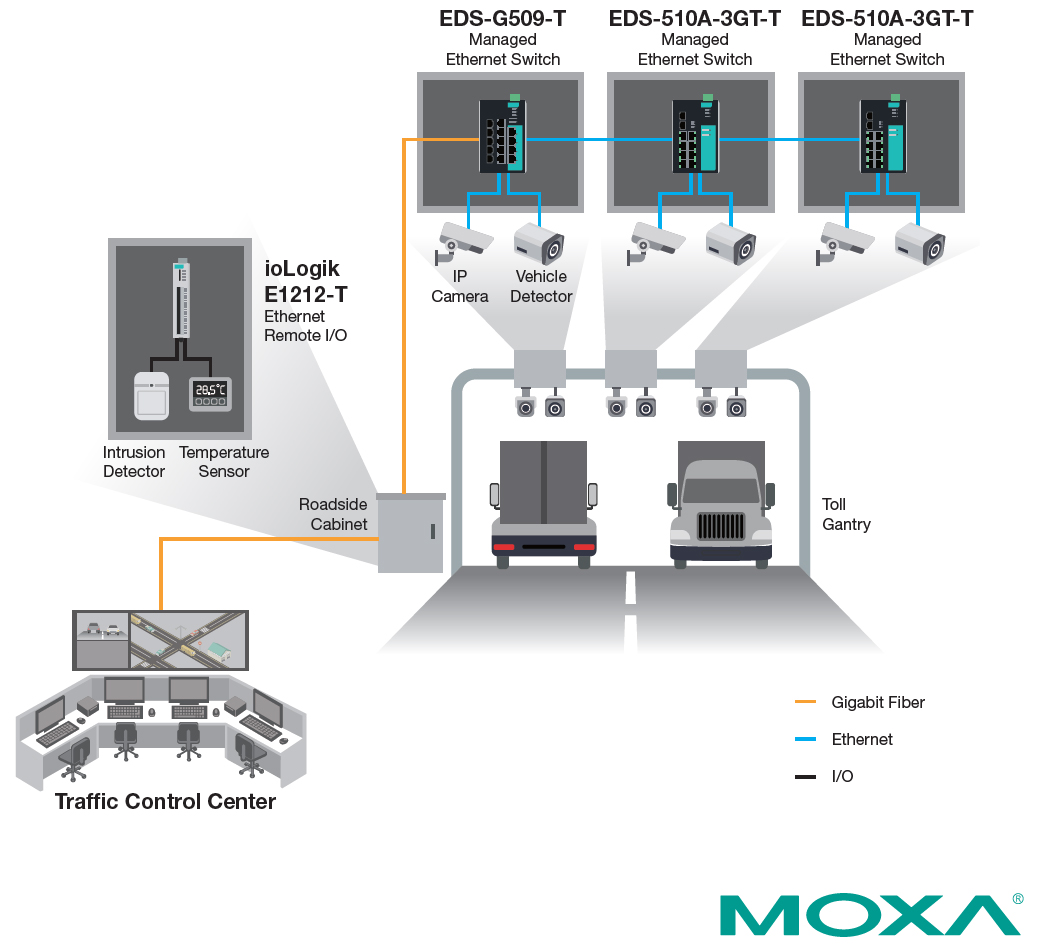

Transportation authorities in France have instituted an environmental tax for all Heavy Goods Vehicles (HGVs) traveling on a national highway network that stretches over 1,500 km. The tax payment of each HGV will be determined by the onboard GPS devices. When a HGV is not compliant with the tax program, a eparate system will capture a snapshot of the license plate and send it back to the traffic control center for toll enforcement.

To collect data from numerous vehicle detectors and cameras of over 150 toll gantries, Moxa's EDS-G509-T and EDS-510A-3GT-T Gigabit managed switches are deployed to transmit large volumes of images and transaction data to the traffic control center. The EDS-G509-T is also equipped with 5 fiber ports to enable long-distance transmissions along national highways. Inside roadside cabinets, our compact ioLogik E1212-T remote I/O connects to temperature sensors and intrusion detectors for monitoring the cabinet conditions to enhance equipment safety and reliability.

To collect data from numerous vehicle detectors and cameras of over 150 toll gantries, Moxa's EDS-G509-T and EDS-510A-3GT-T Gigabit managed switches are deployed to transmit large volumes of images and transaction data to the traffic control center. The EDS-G509-T is also equipped with 5 fiber ports to enable long-distance transmissions along national highways. Inside roadside cabinets, our compact ioLogik E1212-T remote I/O connects to temperature sensors and intrusion detectors for monitoring the cabinet conditions to enhance equipment safety and reliability.

System Requirements

- High-performance network backbone to transmit large volumes of data back to the traffic control center

- Wide-temperature tolerance for outdoor operation

- Rugged and compact remote I/O for roadside cabinet monitoring

Why Moxa

- Gigabit fiber network backbone for massive video and data transmissions over long distances

- -40 to 75°C wide temperature range

- Compact remote I/O for environmental monitoring inside space-limited cabinets

Moxa Products

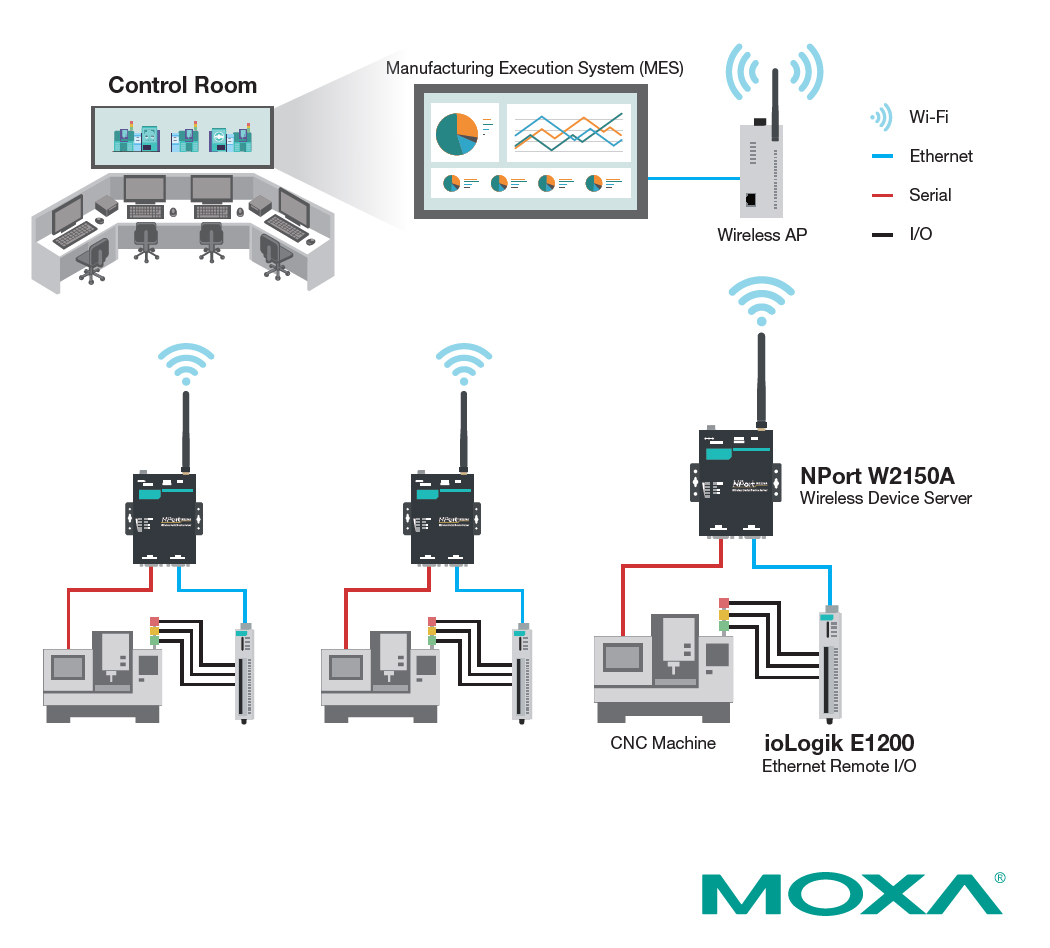

CNC machines enhance productivity efficiency and accuracy in the manufacturing industry. A CNC system integrator in Europe develops connectivity between CNC machines and manufacturing execution systems (MES) to allow factory operators to control and monitor CNC machines at the control center. By enabling connectivity, engineers can receive CNC machine status and operational conditions to optimize system operations.

The production site houses numerous CNC machines and other equipment. The layout of the manufacturing floor made it hard to wire the machines and other necessary equipment. Each CNC machine consists of devices and sensors that use different communication interfaces. Moxa's solutions included ioLogik E1200 remote I/Os, which were deployed to collect a variety of DI and AI data, and NPort W2150A wireless device servers, which were deployed to collect serial data directly and I/O data from the ioLogik. The data is then transmitted through wireless networks. With our connectivity solutions, operators can easily monitor CNC machine status through MES located at a remote control center.

The production site houses numerous CNC machines and other equipment. The layout of the manufacturing floor made it hard to wire the machines and other necessary equipment. Each CNC machine consists of devices and sensors that use different communication interfaces. Moxa's solutions included ioLogik E1200 remote I/Os, which were deployed to collect a variety of DI and AI data, and NPort W2150A wireless device servers, which were deployed to collect serial data directly and I/O data from the ioLogik. The data is then transmitted through wireless networks. With our connectivity solutions, operators can easily monitor CNC machine status through MES located at a remote control center.

System Requirements

- Collects both I/O and serial data from CNC machines

- A wireless solution that overcomes the difficulties of wiring in the factory due to its manufacturing floor layout

- A variety of I/O interfaces for different types of CNC machines

Why Moxa

- One-stop-shop solution from I/O and serial connectivity to wireless communication

- Supports a variety of I/O interfaces to fulfill various demands from CNC machines

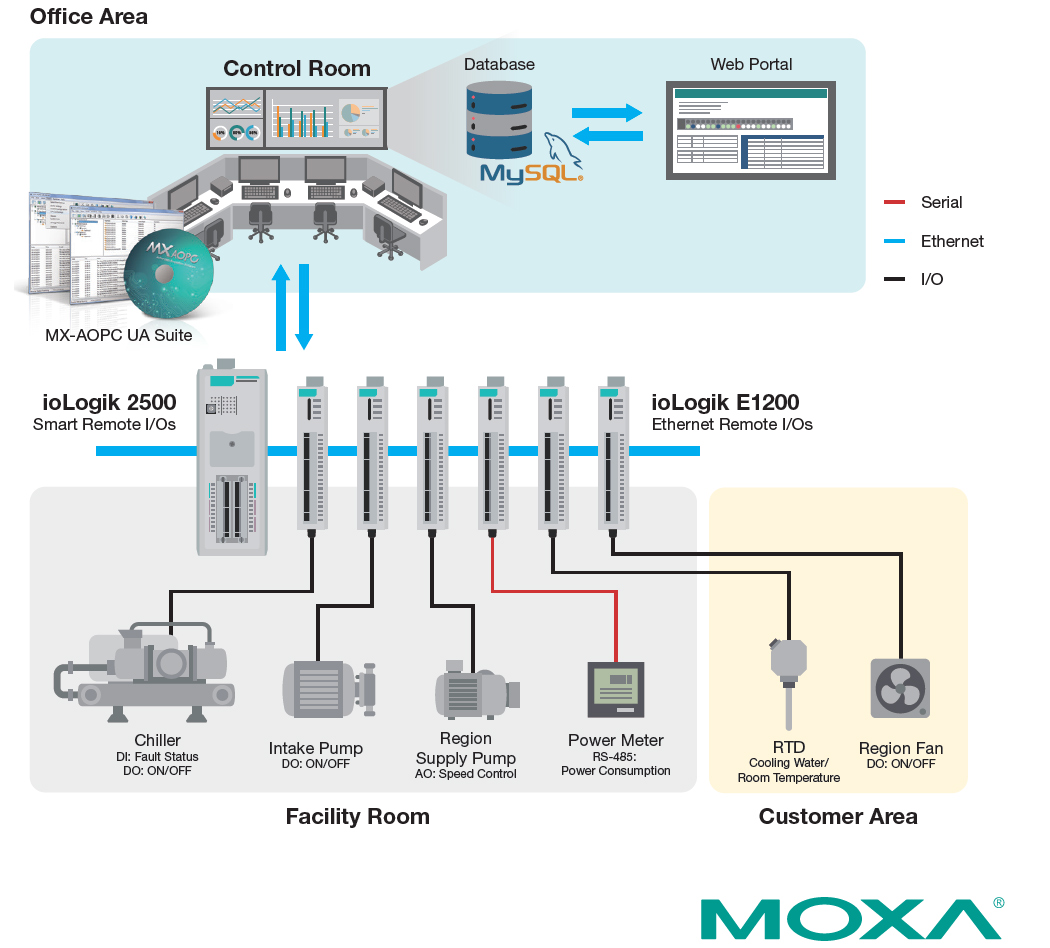

HVAC systems are mostly used in buildings to provide comfort and acceptable indoor air quality. However, they also consume massive amounts of energy. In order to optimize energy consumption, a hypermarket operator wanted to monitor the power usage in their HVAC systems. Most importantly, they wanted to enable automated demand response control, based on the real-time temperatures in the hypermarket during business hours, to decrease the activation time of chiller systems and help the hypermarket save energy and reduce operating costs.

To automatically enable the settings adjustment of the chiller, pump, and fan, our ioLogik 2500 smart remote I/Os were used to provide programming-free control logic through our unique Click&Go Plus function. Also, our ioLogik E1200 Ethernet remote I/Os were deployed to collect serial, digital, and analog data from chillers, pumps, power meters, and resistance temperature sensors (RTD). In addition, our remote I/Os come with MX-AOPC suite, making the integration of a variety of field data acquisitions into your database (i.e., MYSQL database) easy.

To automatically enable the settings adjustment of the chiller, pump, and fan, our ioLogik 2500 smart remote I/Os were used to provide programming-free control logic through our unique Click&Go Plus function. Also, our ioLogik E1200 Ethernet remote I/Os were deployed to collect serial, digital, and analog data from chillers, pumps, power meters, and resistance temperature sensors (RTD). In addition, our remote I/Os come with MX-AOPC suite, making the integration of a variety of field data acquisitions into your database (i.e., MYSQL database) easy.

System Requirements

- Automatically controls HVAC systems based on business hours and temperatures to save energy

- Requires DI, DO, AO, RTD, RS-485 interfaces for different types of data collection and machine control

Why Moxa

- Easy-to-use Click&Go Plus function enables simple logic control for HVAC systems

- Expansion capabilities by supporting various interfaces and protocols in one device (e.g., DI/DO, AI/AO, RS-485, Ethernet)

- Supports an active tag to send I/O and serial data to the MX-AOPC UA Server for HMI integration