IEC 61850 New Subtations Reliability

Noise Guard?: Wire Speed Zero Packet Loss Technology

- IEC 61850 New Subtations Reliability

To meet IEEE 1613 Class l requirements, network devices must have a level 4 EMC rating to guarantee they will be able to reliably tolerate high EMI conditions.

Critical packet prioritization

- Mechanical Design: Integrated housing for better conduction

- Customized Components: Newly redesigned fiber transceiver

- Enhanced Power Supply Unit: Optimized circuit design, with upgraded components

Fiber Interface Diagnosis with Fiber Check?, for ST, SC, or SFP

Using Fiber Check?, substation switches can monitor ST/SC (as well as SFP) connectors, and notify power SCADA systems via SNMP trap or MMS when abnormalities are detected, allowing operators to initiate maintenance procedures.Fiber Check? reports and alarms can be communicated via the network, CLI, or serial console; via MMS reporting or SNMP traps; by a digital relay; or in the system log. Preferably, several methods will be used to provideredundancy. This arrangement also allows system operators to monitor things like transmission and reception power, temperature, and voltage/current along optical fiber connections, in real time.

- Fiber status monitoring: Fiber temperature, working voltage, Tx/Rx power

- Auto-warning: SNMP trap, relay, email, MMS, event log

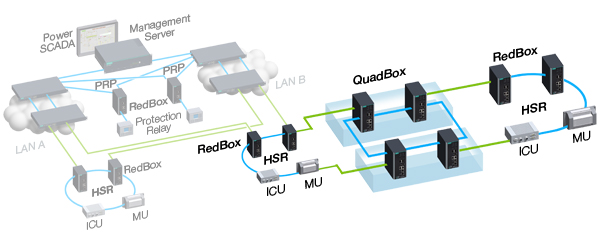

Versatile & Scalable PRP/HSR Network

Moxa?s PT-G503-PHR-PTP RedBox is a PRP/HSR all-in-one device that supports Gigabit, PTP, Coupling, and QuadBox for versatile and scalable zero switch-over time networks that are easy to manage and deploy.

Coupling

QuadBox

OS Smart Recovery: Remotely or Automatically Trigger a Computer to Restore its Entire Software Environment

Moxa Smart Recovery? allows engineers to automate the remote monitoring of a computer?s health and trigger OS re-writes should a problem arise. These re-writes are made from a tagged copy of the entire systemthat is stored locally on the computer, created when the embedded computer was first successfully deployed.

Without a smart OS recovery system, corruption of system software?whether in the OS or in local substation applications?can mean catastrophic failure for remote industrial installations and sites with mass computer deployments. With some estimates of computer failure attributable to software corruption as high as 30%, automated BIOS-level software recovery systems are an extremely valuable design addition to power substationinstallations.

One-click OS image generation tool

Automatic or one-click Moxa smart recovery tool

- Power Shutdown:

- System slowdowns:

Configure periodical recoveries to speed things up - Bootable but damaged systems:

Configure a rewrite procedure that will let you know if the damage is in hardware or software - System crash and boot failure:

Use auto-recovery to verify if the problem is with hardware or software, and resurrect the machine if it?s a software problem

Auto boot up

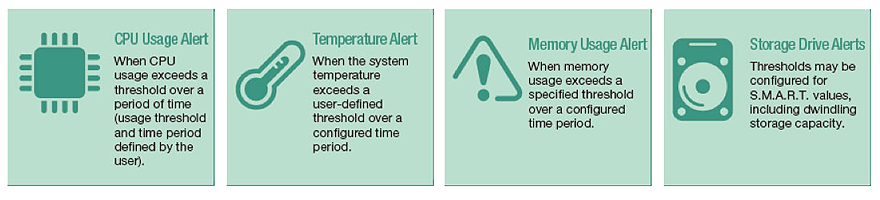

Self-Health Management and Alerts

Automatically check the status and capacity of a computer and issue alerts when the status does not match expected criteria

Synmap, Moxa?s revolutionary software virtualization for industrial computers, is an evolutionary advance in network device control that adapts solid, reliable SNMP into a fully portable remote procedure interface.Synmap not only provides SNMP functionality, but also allows remote monitoring and control of device internals like temperature, BIOS parameters, and local interfaces. Synmap is SNMP-based health management and alertsoftware, and Synmap devices are a flexible and cost-effective upgrade that returns obvious benefits to any IA network.

| Pre-defined Event | Threshold | Default activation | Action | |||

| Item | Description | Min | Max | Default | Output to relay | |

| CPU | CPU usage alarm: When CPU usage reaches a pre-defined threshold. | 1% | 100% | 80% | Disabled | CPU Usage Warning |

| Memory | Memory usage alarm: When memory usage reaches a pre-defined threshold. | 1% | 100% | 80% | Disabled | Memory Usage Warning |

| Disk | Storage partition usage alarm: When storage usage reaches a pre-defined threshold. | 1% | 100% | 80% | Disabled | Disk Partition Usage Warning |

| Temperature | CPU Temperature alarm: When the temperature exceeds a pre-defined threshold. | 0°C | 120°C | 100°C | Disabled | High temperature warning |

| Mainboard Temperature alarm: When the temperature exceeds a pre-defined threshold. | -40°C | 0°C | -15°C | Disabled | Low temperature warning | |

| 0°C | 120°C | 100°C | Disabled | High temperature warning | ||

| Network | Ethernet Status alarm: When an Ethernet port link is down, output to relay | N/A | N/A | N/A | Disabled (by port) | Link down warning |

| Power | Redundant power monitor and alarm: When one of the power modules malfunctions (dual power model) | N/A | N/A | N/A | Disabled | Power Failure Alarm Default: Disabled |

Patented Fanless Thermal Design with Wide Temperature Tolerance

A broad temperature tolerance is required in any substation environment, where temperatures may run as high as 75°C or as low as -40°C. Most computers fail when faced with these extremes. The challenge electricity suppliers face is how to guarantee that their systems will continue to function reliably and predictably even when faced with the most extreme environmental challenges.

Patented Heat Dissipation

Moxa's rackmount embedded computer patented heat dissipation fanless design with wide temperature tolerance.

To endure harsh environments and ensure optimal operating performance even at high temperatures, Moxa introduced its patented L-type? heat sink. The L-type? heat sink is a heat dissipation mechanism that cools down the unit's internal temperature, and works by placing a plate in direct contact with the chief heat source inside the unit.

- Maximizes heat dissipation by keeping the sinks close to the heat source

- Highly efficient heat pipe engineering

- Stackable, for close-in rack use

FloTHERM CFD Simulations for Heat Optimization

After many years of using FloTHERM to refine our development techniques, Moxa may now call upon a rich catalog of past methods, designs, and evaluated components when creating new devices. This database gives our engineers a wealth of component information, allowing them to easily evaluate a wide range of approaches for achieving specified thermal tolerances. By using FloTHERM?s advanced modeling techniques, our engineers can quickly and easily create virtual models of electronic equipment that allow them to effectively analyze the thermal limits of proposed modifications before any physical prototypes are built.

- Mechanical Design: Integrated housing for better conduction

- Customized Components: Newly redesigned fiber transceiver

- Enhanced Power Supply Unit: Optimized circuit design, with upgraded components